A Renaissance Renovation Man

Our ensuite bathroom urgently needed a rhytidectomy. A face-lift. Right from the beginning, we knew Cam did not want to take on the entire project by himself, but we did not know any contractors or tilers in this area. We began with the big box store renovation departments but came away unimpressed. Cam asked around and, after many phone calls, finally connected with Vince who promptly came to have a look at our bathroom and give us a quote. Vince is retired and takes on small jobs to stay busy and because he loves the work. His modus operandi is to give his clients a list of required materials, have the client purchase and pick up/have delivered those items and pay him only for his work. Fine with us, but even though we were eager for him to do our renovation, before he’d take us on we had to go to his home to view his bathroom so we could see the type/quality of work he does. His work is splendid; he is a perfectionist and very proud of his work and rightly so. He then accepted our job and we were chuffed.

The scope of the job included demolition, plumbing, electrical, carpentry, cement work, tiling and grouting. As to the wrecking of the old, besides cutting the fibreglass shower stall in half and carting it away, demolition included removing the false ceiling over the shower stall, the two side walls that narrowed the space and the janky fluorescent light fixture that was simply “laying” atop the false ceiling:

Demolition complete:

Plumbing included moving the drain to the new centre of the shower stall floor, raising the outlet to the shower head to accommodate two people whose height exceeds 185cm, adding an outlet for the new sprayer, and some pipe art, necessitated by Moen. As do most folk, we purchased a kit that included a tap, shower head, sprayer, pressure valve and diverter. At Vince’s encouragement, we chose Moen which, apparently, has both the best reputation and the best warranty, except…

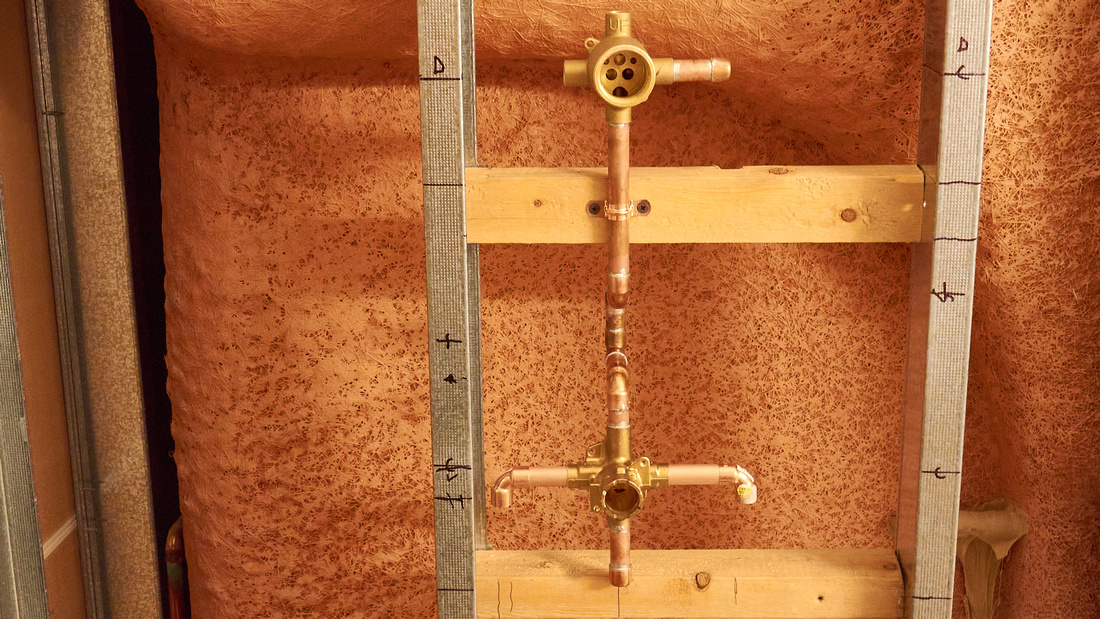

The diverter and the tap did not align. Both made by Moen but they did not align. The diverter was 1/2” farther back than the tap. Vince had a phone call with Moen. The rep suggested to him that the copper pipe be bent. Vince would have none of that! Cam had a live on-line chat with a Moen rep, with no success. Eventually, Cam devised the solution — make a series of 90° joins in the copper pipe, using slightly different lengths of pipe, to create the 0.5 inch adjustment. Vince executed the plan flawlessly. Veritable pipe art:

It looks a bit like a musical instrument, non?

This project also included construction. The exterior wall studs — a combination of metal and wood — needed shimming to level the wall. There was no pony wall so it had to be built from scratch. This was a complicated and interesting process. At the end of the pony wall, there has to be an anchoring post. It cannot move. Ever. To ensure its rigidity, Vince cut a hole in the floor, ran the post down through the floor to the basement where he attached it, with braces to the floor joists. Then it was rock-solid. Next, cement board which isn’t cement board after all but a new, high-tech version of waterproof wall board, and that completed construction.

With the shower stall space framed and prepped, the next job was the shower floor. First membrane, then cement:

Finally, time for the tiling which was a study in mathematics, geometry, artistry, accuracy, and comprehensive planning. It was both an education and a pleasure watching such an experienced and precise craftsman at work. Templates were made for everything. For instance, rather than patching around the bench, which would have been the quickest and easiest option, “slots” were cut in the tiles at both sides so the bench could be fitted into them before being affixed to the walls.

Finally, time for the tiling which was a study in mathematics, geometry, artistry, accuracy, and comprehensive planning. It was both an education and a pleasure watching such an experienced and precise craftsman at work. Templates were made for everything. For instance, rather than patching around the bench, which would have been the quickest and easiest option, “slots” were cut in the tiles at both sides so the bench could be fitted into them before being affixed to the walls.

Everything was planned with an eye to the finished product. Nothing was left to chance. Never once “that’ll do”. Accurate measurements done over and over again, wall and floor tiles laid out on our living room floor — hours spent arranging and rearranging, long before the cement was mixed and the tiles set. Then more templates were made - for the floor area and for the cuts needed to those tiles. We’ve had tiling done before, indeed Cam himself has done some, but never with this degree of exactitude and mastery.

Everything was planned with an eye to the finished product. Nothing was left to chance. Never once “that’ll do”. Accurate measurements done over and over again, wall and floor tiles laid out on our living room floor — hours spent arranging and rearranging, long before the cement was mixed and the tiles set. Then more templates were made - for the floor area and for the cuts needed to those tiles. We’ve had tiling done before, indeed Cam himself has done some, but never with this degree of exactitude and mastery.

Between each of the tiles is a spacer, and slotted into each spacer is a wedge (an orange wedge in our case), that keeps the tiles level (even).

Vince is a true renaissance man! He is a master tiler, a plumber, a gardener, an inventor, and a musician. He’s a mathematician, which became obvious with all the complicated calculations and the creation of all the templates. Over the course of our renovation, Vince brought his harmonica to our home twice, his pan flute and his accordion once each. Ohmigosh, can he ever play! He kept us in leaf lettuce from his greenhouse, and pears from his neighbour’s tree and twice brought us his own prosciutto to eat with his wife’s homemade caraway seed bread for our lunch. He is funny and clever and creative, and kind and friendly and meticulous and a very hard worker. Cam and I are the luckiest two ever, to have found such a gem! Happily, I feel very sure we’ve made a friend for life in this sweet, generous and talented gentleman.

Vince is a true renaissance man! He is a master tiler, a plumber, a gardener, an inventor, and a musician. He’s a mathematician, which became obvious with all the complicated calculations and the creation of all the templates. Over the course of our renovation, Vince brought his harmonica to our home twice, his pan flute and his accordion once each. Ohmigosh, can he ever play! He kept us in leaf lettuce from his greenhouse, and pears from his neighbour’s tree and twice brought us his own prosciutto to eat with his wife’s homemade caraway seed bread for our lunch. He is funny and clever and creative, and kind and friendly and meticulous and a very hard worker. Cam and I are the luckiest two ever, to have found such a gem! Happily, I feel very sure we’ve made a friend for life in this sweet, generous and talented gentleman.

My best advice to anyone planning a bathroom renovation — find yourself a Vince!

My best advice to anyone planning a bathroom renovation — find yourself a Vince!

’Til next time, y’all…